Projects

About the project

About the project

This project will improve milk quality through best-practice snap-chilling and a new farm vat ideal for New Zealand conditions.

Subproject 1

- Now complete, this prototyped an ice-bank using phase-change materials, better performed and less expensive than any current model. Proven at full-scale on-farm.

Subproject 2

- This project is focused on designing the best practice future vat, a stainless-plastic hybrid, to hold snap-chilled milk. Safer to maintain and cheaper to build it will have low-shear agitation and pump-less emptying.

Subproject 3

- This project is stretchy: 3D-printing tank insulation with in-built strong zones to support a light stainless liner.

Want to know more, or be involved?

Read article in FoodNZ magazine Contact: Professor Richard Archer or Professor Mohammed Farid About the project

About the project

This project seeks to freeze sheep or goat milk on-farm fast enough to keep it intact after months in storage. Current freezing in bags or pails kills the milk in weeks and safe thawing is challenging.

It has developed a simple, affordable, robust, low-maintenance rapid on-farm milk freezer that preserves the sheep milk without loss of functional value. It should also suit colostrum, plasma, blood, and other milks. The frozen form is easy to store, handle, transport, measure and thaw.

Want to know more, or be involved?

Read article in FoodNZ magazine

and read article: Sheep milk freezing FNZVol20No1

Also read the article: Sheep milk freezing FNZVol21No2

Contact: Dr Lindsay Robertson

About the project

This project will develop a combination of processing technologies that will enable the New Zealand meat industry to transform low-value meat cuts into premium export products.

The proposed new technologies include sous vide tenderisation (SVT) at industrial scale, enzyme tenderisation, potentiated and controlled using new adjunct technologies high pressure processing (HPP) and pulsed electric field (PEF) processing.

Want to know more, or be involved?

Read article in FoodNZ magazine

And read article Meat enzymes -FNZJune 2020 Vol20No3

Contact: Dr Mike Boland

About the project

About the project

In this project we propose a new device which will allow, for the first time, precision control of smoke generation. It will be able to provide smoke with a ‘tunable’ flavour profile, while minimising or eliminating polycyclic aromatic hydrocarbons (PAHs).

Our work builds on several unique New Zealand factors:

- that the smoking industry in New Zealand pre-dominantly uses mānuka, which has a growing international reputation,

- that there is a rapid expansion of artisanal processed food products, and

- there is growing interest in the use of smoke and charcoal in kitchens and restaurants.

This is a distinct and new opportunity to New Zealand products and an opportunity to export equipment. We will use mānuka as the first exemplar – mānuka has a clear and unique New Zealand flavour signature, with known properties embedded in mātauranga Māori.

Project outputs include a smoking device that delivers:

- dial-up aroma profiles,

- compliant PAH content,

- smoke consistency, and

- copes with variation in atmospheric humidity.

Want to know more, or be involved?

Read article in FoodNZ magazine

Contact: Professor Jim Jones or Dr Graham Eyres

About the project

About the project

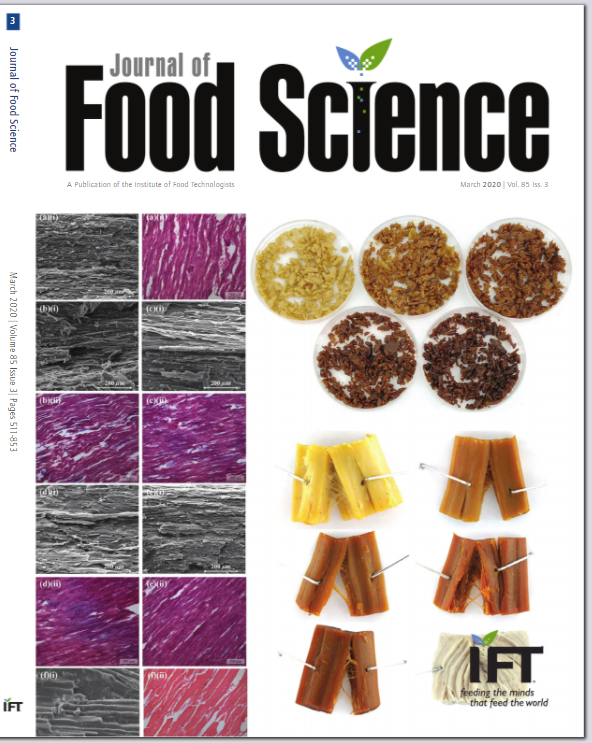

The aim of this project is to develop a process to render meat trimmings into soluble proteins and large peptides with minimal hydrolysis and low phosphate content. It will also look to emulsify and partially hydrolyse fat, and to release sugar monomers from connective tissues so they are free to participate in Maillard reactions.

In addition, this project aims to understand how animal proteins (meat or dairy) can be intimately associated with plant proteins to make up structures simulating fibrous tissues.

Work in this project was wound up in January 2018, apart from the PhD project that will continue to completion.

Want to know more, or be involved?

Read article in the Journal of Food Science 2020

Contact: Dr Santanu Deb Choudhury or Dr Michael Parker

About the project

This project has prototyped a compact industrial process to render apple (or other) pomace into a light fawn ingredient powder at solids yields over 80% (stalks, pips, labels and some skin are rejected).

The ingredient product is a careful mix of insoluble and soluble fibre. On reconstitution it has high water holding and thickening capacity and is smooth on the mouth. It is suitable as:

- an encapsulant for spray drying;

- a gluten-free baking aid;

- a nutritional high-fibre ingredient product; and

- an anti-caking agent.

This project has been very successful, with significant commercialisation interest from New Zealand companies.

Want to know more, or be involved?

Read article in FoodNZ magazine

Also read the article: CreamedPomaceFNZVol19No6

Contact: Professor Richard Archer, Dr Lee Huffman or Dr John Bronlund

About the project

Originally titled Spray Drying, this project now focuses on the suite of PUO’s broadly classified as thermal drying. It develops fundamental prediction methods to enable drying of sticky foods with no, or very little, drying aid. Also, it investigates spraying of fibre-containing liquids.

The applications are wide, across all sectors wanting to produce dehydrated powders. This project investigates one use of the product from the Pomace Fracturing project.

The project will run until mid-2021.

Want to know more, or be involved?

Read article in FoodNZ magazine

and read article: Drying sticky products FNZvol20No6

Contact: Professor Richard Archer, Professor Tony Patterson or Dr Lee Huffman

About the project

This project has prototyped a hybrid dryer, using heat pump plus desiccant wheel to achieve very low dew points at low temperatures. It can dry products from frozen at lower temperatures than experienced during normal vacuum freeze drying.

Suited to large scale continuous operation, it offers lower capital and operating cost than vacuum freeze drying, and may be better for delicate low-sugar materials such as flowers, leaves, roots, glands, shell fish and some fruits and vegetables.

A pilot unit at 10 kg/day water removal, and smaller batch units, are available for trialling products.

Want to know more, or be involved?

Read article in FoodNZ magazine

Also read the article: Atmospheric freeze drying FNZVol21no2

Contact: Professor Richard Archer or Dr Lee Huffman

Pulsed Electric Field and High Pressure Processing

About the project

To develop within New Zealand expertise, engineering knowledge and equipment in Pulsed Electric Field (PEF) and High Pressure Processing (HPP) technologies.

This will enable New Zealand companies to manipulate raw material properties to enhance raw material values, enhance the extraction of functional compounds (bioactives, flavour), improve yields and/or enhance the product’s health attributes.

Currently this project is focused on technology for the potato and wine industries, developing:

- an internationally relevant PEF based treatment for potatoes to reduce costs and enhance the quality including the impact of Liberibacter infections

- a PEF treatment for grapes that reduces cost and increases flavour compound extraction efficiency while ensuring more consistent wine.

Want to know more, or be involved?

Read article in FoodNZ magazine

Or read in FOODNZ Use of Pulsed Electric Fields technology for the NZ winemaking industry

Contact: Professor Indra Oey or Professor Mohammed Farid

Pasteurisation and Sterilisation Technologies

About the project

About the project

This project targeted new technologies of paired PUOs (e.g., thermal + HPP) that together achieve pasteurisation and sterilisation at lower thermal stress for heat sensitive foods.

While basic research in the project was completed in January 2018, product development and commercialisation opportunities are continuing.

Want to know more, or be involved?

Read article in FoodNZ magazine

Contact: Professor Mohammed Farid

About the project

This project aims to develop commercial applications for microwave assisted processing.

This project brings to New Zealand modern microwave-heated pasteurisation and pressure sterilisation of packaged food or RTE meals. It will use the Meyer Burger pilot industrial CiMPAS unit recently installed at Massey University Palmerston North. The FIET project is developing rapid validation techniques for regulatory approval to permit fast commercialisation of new products and newly tuned heating profiles.

The capability is also available to support companies developing shelf-stable, heat-sensitive packaged foods, or any application of microwave-assisted processing.

Want to know more, or be involved?

Read article: MicrowaveAssistedProcessingFNZVol19No4

Also read the article: MicrowaveAssistedTechnologies

Contact: Dr Jeremy Smith

UV Technologies for Fresh Exports

About the project

“Fresh” exports are growing in volume and value. However, microbial contamination can put shelf life and food safety at risk. Ultra violet (UV) technologies can help, but the challenge is to illuminate all the surfaces without over-exposure of any segment of the food. This must be achieved under industrial conditions, gently, reliably and affordably.

This project will prototype a device to expose rolling blueberries uniformly to UV light. The process will optimise fruit motion to maximise disinfection and shelf life and minimise handling damage. The technology will be adaptable to other fragile, round, food products.

Want to know more, or be involved?

Read the article: UVTechnologiesFNZVol19No2

And read Rolling Berries FoodNZFebMar21

Contact: John Bronlund

About the project

About the project

This project will apply modern hyperspectral image capture and analysis to two New Zealand applications with current needs.

Subproject 1

- A hyperspectral video camera will inspect potatoes rolling on a grading line and determine if individual tubers have too much potato-psyllid damage (through liberibacter infection) for processing. A robotic arm will pick out failing potatoes.

Subproject 2

- The hyperspectral camera will inspect frames of honey within the extraction plant, and predict the “mānukaness” of each individual cell. The line operator can set threshold values for extraction as mānuka or as another class of honey.

Want to know more, or be involved?

Read the article: Spectral Separations Article FNZVol19No3-2

Contact: Professor Richard Archer